The Dichotomy…

The wind turbine earthing system design calls for the Effective Earthing of Wind Turbine Generators, there begins the dichotomy…

Wind turbines generators, WTGs, often installed in electrically ‘difficult’ areas. Also, selecting the locations primarily for their airflows. Therefore, the location may appear good from a civils or planning perspective. However, very often quite remote from the energy networks. Positioned on high resistivity rocky ground, e.g. hills. Therefore, in these circumstances, ensuring that the wind turbine earthing design performs effectively is critical to protecting life. Additionally, it can be limiting when considering the types of earthing available for WTGs.

Wind Turbine Earthing System – The Brief

GreyMatters recently asked to consult on an effective wind turbine earthing system design for a generator bin West Wales. Also, with the intention to build this wind turbine on a farm. Furthermore, with the HV connection also to supply the domestic and industrial electricity for the farmhouse and yard. As a result of this, it’s critical to ensure that the ‘hot-zone’ in the case of a fault did not encroach on the farmhouse or yard.

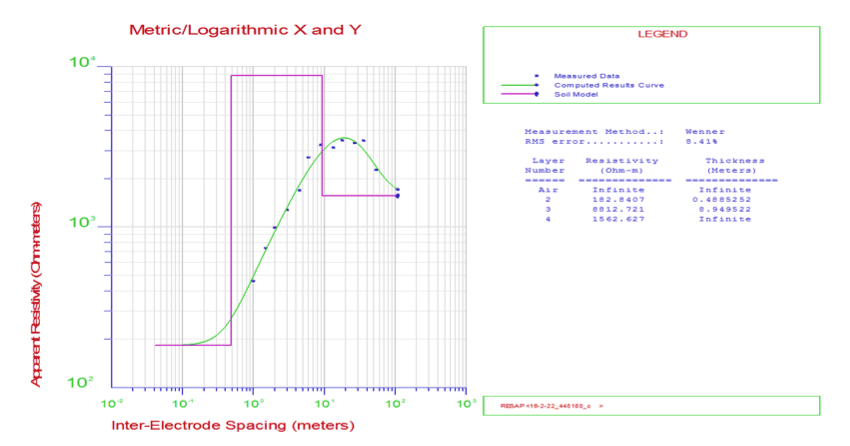

Local Geology

With the soil resistivity in the 3,500-9,000 Ω.m at the intended site location. So any electrical earthing system design will need to recruit a large amount of geology in order to provide adequate earth resistance.

Wind Turbine Earthing System – The Solution

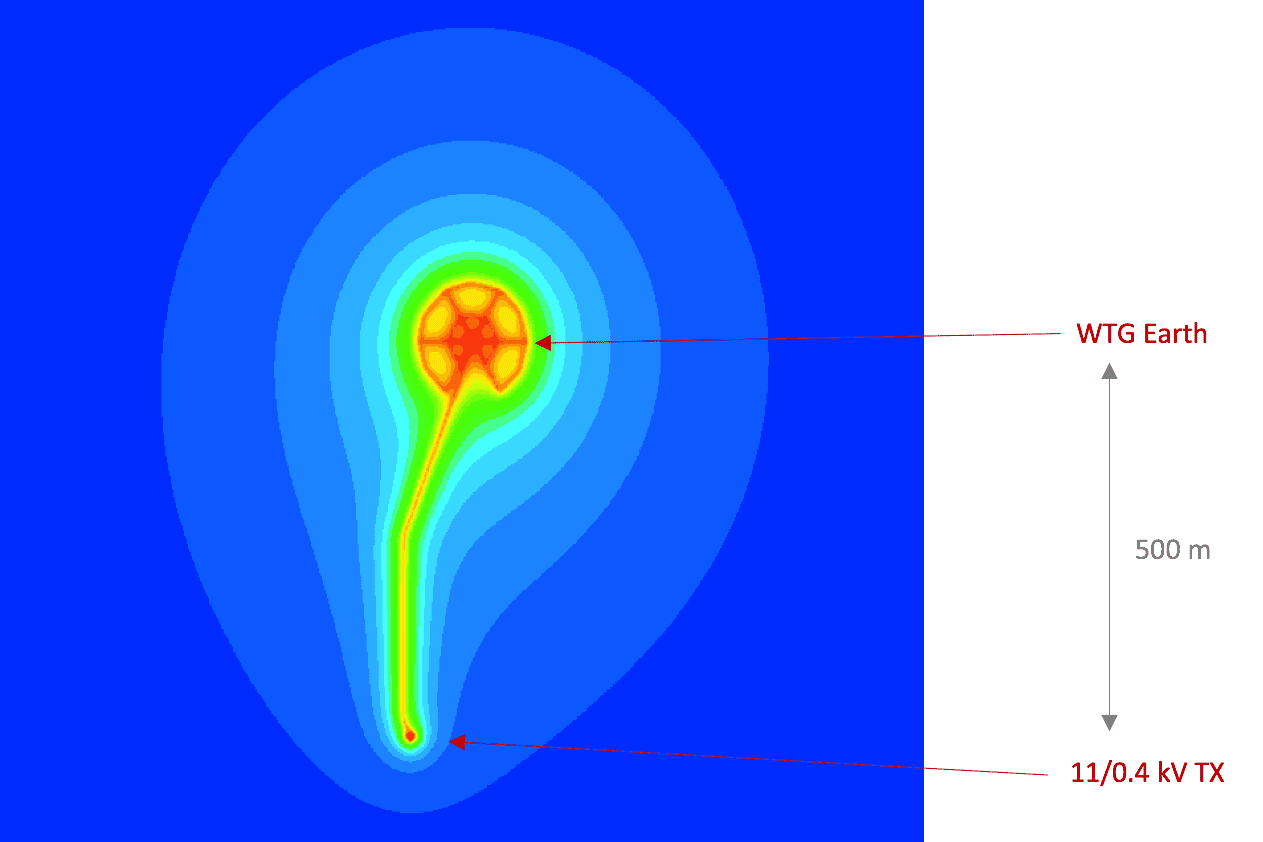

As a result, effective earthing in the wind turbine generators achieved by using deep-bored earth electrodes. Arranged in a spoke configuration around the turbine base. This provides an effective earthing network at the turbine end of the system both for the electrical earth and connection as well as lightning protection.

The HV point of connection is to be located approximately 500 m from the turbine. Closer to the farmhouse. A bare copper conductor, installed in the base of the cable trench extends the earthing system, and a top-hat configuration installed around the base of the substation to control step and touch voltages.

To prevent the transfer of potentials into the LV electrical supply for the farm. A large capacity isolation transformer is specified, in partnership with the turbine supplier. Due to the high resistivity encountered, in preference to the TT Earth method, the wind turbine’s LV supply used a combined hot bonded approach, where the HV and LV earth are combined to prevent any touch voltage hazards within the turbine itself.

Post Completion Monitoring

After Construction is completed, GreyMatters is providing InSite electrical earthing system monitoring to ensure that the installed earthing system performs as designed for the life of the turbine.

If you also have a dichotomy – happy to discuss. Use the Contact Us form or Live Chat tool below.